Turkey on Wednesday witnessed an opening of the first integrated solar panel manufacturing facility, which promises to place Turkey among the leading nations in the renewable energy area.

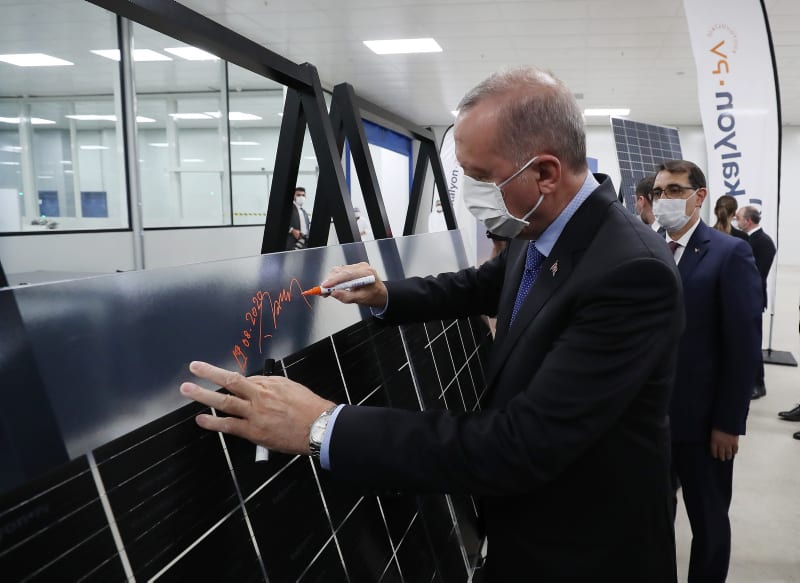

Established in the capital Ankara’s Başkent Organized Industrial Zone, the major solar ingot-wafer-module-cell production factory was opened in a ceremony attended by President Recep Tayyip Erdoğan.

“The facility, which will be implemented through an investment of $400 million and will employ 1,400 people, will place Turkey among leading nations in the renewable energy area,” Erdoğan said in his speech.

It will be manufacturing solar panels with a capacity of 500 megawatts per year and prevent millions of dollars of imports.

“Turkey has come to a position where it manufactures technology in renewable energy,” Treasury and Finance Minister Berat Albayrak said in his speech at the ceremony, expressing beliefs that the country will move forward in other technology areas as well.

“One by one, we are taking steps to end our country’s external dependency,” Albayrak said. “We are starting to produce our national energy with our clean and independent energy technology,” the minister said on Twitter prior to the opening.

Implemented with an investment of around $400 million, Kalyon Group’s facility will produce components for Turkey’s biggest solar power plant, which will be established in the Karapınar district of the central Anatolian province of Konya as part of the first solar Renewable Energy Resource Zone (YEKA) tender with a capacity of 1,000 megawatts.

Kalyon Holding, together with a South Korean Hanwha Q-Cells consortium, won the tender for Turkey’s biggest solar power plant project – the Karapınar Renewable Energy Resources Zone Project – in March 2017 at a cost of $0.0699 per kilowatt-hour. However, Hanwha will not continue with the project and China Electronics Technology Group Corporation (CETC) has stepped in to construct the facility and to provide additional two years of technical assistance after the turnkey contract expires.

Under the tender rules, solar components are to be produced locally, and the tender also stipulates that local engineers should constitute 80% of the project’s workforce.

The construction of the module cell factory to produce four units – ingot, wafer, module and cell, was inaugurated at a groundbreaking ceremony in December 2017. The officials had earlier said the factory would begin its operations on June 15.

The plant, which will be manufacturing solar panels with a capacity of 500 megawatts per year, will provide employment to around 1,400 people. The plant is also expected to have a significant contribution to reducing the country’s trade deficit as it is said to prevent $100 million worth of solar panel imports per year.

The components produced at the facility will be used for Karapinar YEKA in the first three years of operations, after which the Turkish company might explore supplies to other local projects and international markets.

“The factory will add to the dynamism of the renewable energy industry,” Energy and Natural Resources Minister Fatih Dönmez said in his speech.

The facility holds a significant place in Turkey’s national energy policy. Two-thirds of the country’s electricity generation is derived from domestic and renewable resources, Albayrak said on Tuesday.

“Turkey’s electricity generation from domestic and renewable resources reached 90% on May 24,” the minister noted.

The country plans to boost its wind and solar capacity by 10,000 MW each year over the coming decade through YEKA. Dönmez had earlier announced plans to hold YEKA tenders for solar energy in a new form, known as “mini YEKA,” which are due to be held this year.

Monocrystalline solar panels

Of the two types of technology most widely utilized in solar panels worldwide, Kalyon’s panel facility will produce the higher efficient monocrystalline solar panels rather than polycrystalline solar cells.

Monocrystalline solar panels are currently the most widely used worldwide and are even expected to become more widespread in the future.

CETC is one of the biggest companies in China and is known for building China’s first satellite, airborne radar and guided missiles, and for developing and manufacturing electronics.